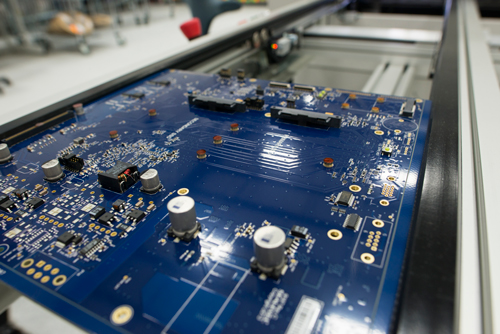

Sealevel’s assembly capabilities are optimized for low to medium volume production. State of the art surface mount line, X-ray, BGA and fine pitch repair can reliably handle even the most sophisticated designs.

Printed Circuit Board Assembly

• Real-time Process Feedback and Control Systems

• Defect Tracking and Trending

• Route Verification

• Real-time Process Alarming

• Barcoding and Batch Lot Tracking

• Feeder Verification

• Electrostatic Discharge Controls (ESD)

• Moisture Sensitive Controls (MSD)

• Customer Deviation and ECO Controls

Certification/Registrations

• ISO 9001:2008 Registered

• ITAR Registered

• DDTC Registered

• CCR Registered

• RoHS Compliant

• ESDS 2020 Compliant

• IPC-A-610 Workmanship Certified

• IPC-7721 Repair Skill Certified

• J-STD-001 Soldering Certified

Automated Screen Printer

with 2D Inspection

Fifteen Head

High Speed SMT

34,500 CPH Placement

Seven Head

High Speed SMT

15,300 CPH Placement

Ten Zone Forced Convention Reflow

Five Camera Automated

Optical Inspection

Two Axis Vibration Table

Thermal Walk In Chamber

Closed - Loop Inline

Aqueous Cleaner with Isolation

Multi - Angle

Transmissive X-Ray

Automated Conformal

Coating

Sealevel’s supply chain management services leverage key vendor relationships to minimize cost and inventory while meeting challenging delivery requirements. Our experienced management works with each customer to create a customized program with optimum cycle time.

Supply Management Services

• Strategic Vendor Models

• Commodity Aligned Procurement

• Supply Kanban

• Vendor Management Inventory (VMI) Programs

• Consigned Materials Strategies

• Bonded Inventory Management Programs

• Life Cycle Strategies

• RoHS and RoHS II Compliance

• Counterfeit Parts Avoidance